Check out these Vibration Apps

Vibration Basics

In the world of industrial operations, the smooth and efficient functioning of machinery is paramount. Unexpected breakdowns can lead to costly downtime, production losses, and even safety hazards. Machinery Vibration Analysis stands as a cornerstone of predictive maintenance, offering a powerful way to listen to the “heartbeat” of your equipment and detect developing problems long before they escalate into catastrophic failures.

At its core, vibration analysis is the process of measuring the vibration signals from a machine, analyzing these signals to identify patterns and anomalies, and then interpreting this information to assess the machine’s mechanical health. Every piece of rotating equipment, from massive turbines and industrial pumps to electric motors and gearboxes, generates a unique vibration signature when in optimal condition. Changes to this signature often indicate the early stages of wear and tear or other developing faults.

How is Machinery Vibration Analysis Done?

Data Acquisition:

- Sensors: Specialized sensors, most commonly accelerometers, are strategically placed on the machine (often on bearing housings) to detect vibrations. Other types of sensors, like velocity transducers or displacement probes, may be used depending on the application and the type of machinery.

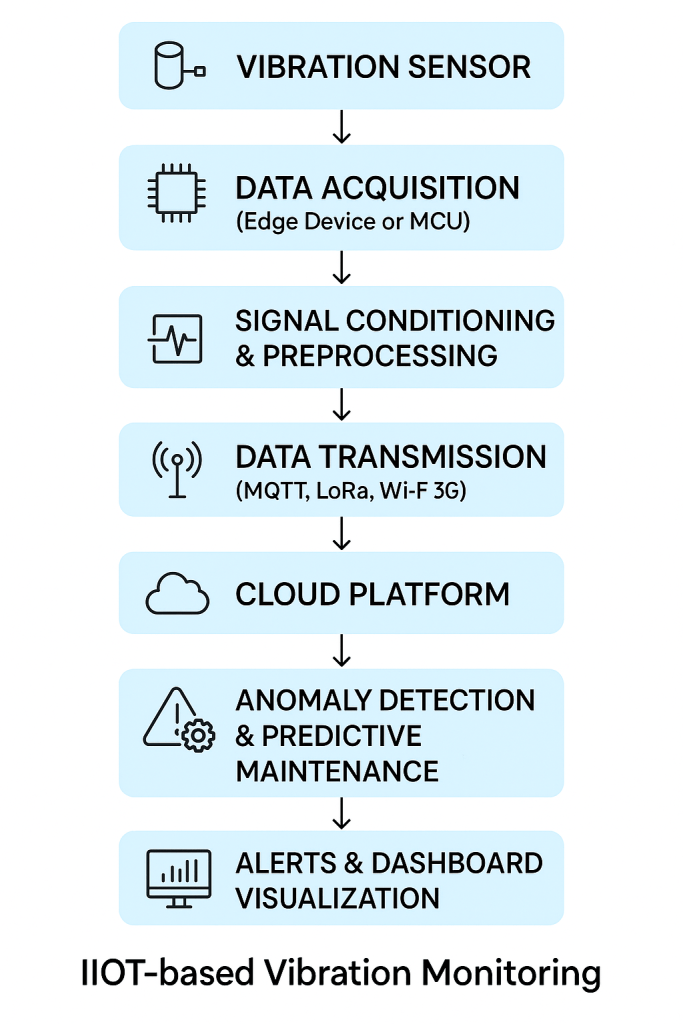

- Data Collectors: These sensors convert the mechanical vibrations into electrical signals. These signals are then captured by portable data collectors during routine inspection routes or by permanently installed online monitoring systems that provide continuous data. Wireless sensor technology is also becoming increasingly common, offering flexibility and ease of installation.

- Wireless Sensors: Nowadays, advanced Triaxial multi-purpose (vibration + temperature + flux density + other) wireless sensors are being used widely in machinery condition monitoring, offering the ability to simultaneously measure vibration in three mutually perpendicular axes (X, Y, and Z) without the encumbrance of cables.

The wireless nature of these sensors greatly simplifies installation, reduces setup time and cost, and allows for monitoring of equipment in hard-to-reach or hazardous locations. By transmitting data wirelessly to a central receiver or cloud platform, triaxial wireless sensors facilitate remote and continuous monitoring, empowering predictive maintenance strategies with richer, more contextualized vibration data for improved asset reliability.

Vibration sensor locations for different machines

| Equipment | Schematic diagram | |

| 1 | Motor operated coupled centrifugal pump | |

| 2 | Motor operated coupled center hung centrifugal pump | |

| 3 | Motor operated coupled centrifugal pump with gearbox | |

| 4 | Motor operated belt-driven centrifugal fan | |

| 5 | Motor operated direct-coupled centrifugal fan | |

| 6 | Motor operated coupled centrifugal fan | |

| 7 | Motor operated belt-driven rotary screw compressor | |

| 8 | Motor operated coupled rotary screw compressor | |

| 9 | Motor operated rotary screw compressor with gearbox | |

| 10 | Diesel generator set | |

| 11 | Cooling tower fan |

Data Processing

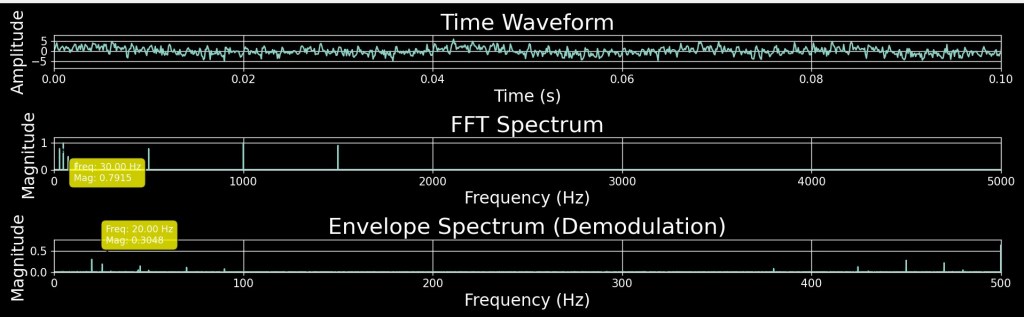

The raw vibration signal is a complex mixture of different frequencies and amplitudes. To make sense of this data, it undergoes signal processing.

- Time Waveform Analysis: This involves looking at the raw vibration signal plotted over time. It can reveal impacting events, modulation, and noise.

- Frequency Spectrum Analysis (FFT): Most widely used diagnostic tool. Using a mathematical process called Fast Fourier Transform (FFT), the time-domain signal is converted into the frequency domain. This creates a “spectrum” – a graph that shows the amplitude of vibration at different frequencies. Each distinct frequency component in the spectrum can often be linked to a specific mechanical component or fault condition.

- Overall Vibration Levels: Sometimes, a simple overall measure of vibration energy is trended over time. A significant increase can indicate a developing problem.

Analysis and Diagnosis

- Trained analysts (or increasingly, AI-powered diagnostic software) examine the vibration spectra and time waveform data.

- They look for specific frequency patterns, changes in amplitude, and the presence of unusual vibration signatures that are characteristic of known fault conditions.

- By comparing current readings to baseline data (taken when the machine was known to be in good condition) and established alarm limits, they can identify the type and severity of the potential problem.